Pressure While Drilling (PWD) Sub

In conjunction with a Pressure Module and a Pressure While Drilling (PWD) Orienting Sub, the ParaTrack-2 system tool is used to measure downhole pressure. It gives real-time measurements of mud pressure both inside the drill pipe and in the annulus just behind the drill bit. Pressure measurements are taken behind the bit when jetting. When using a mud motor the pressure is measured directly behind the mud motor.

The Paratrack-2 tool must be the PWD enhanced version to allow the connection of the Pressure Module as shown in Figure 1.

Pressure While Drilling (PWD) / orienting sub

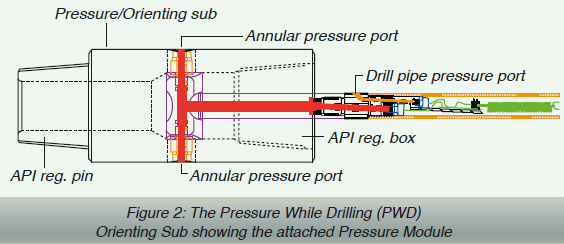

The pressure module has a grease-filled access port in its side for measurement of the pipe pressure and another grease-filled access port at the bottom which allows transport of pressure from the specialized Pressure While Drilling (PWD) / orienting sub as shown in Figure 2. The PWD sub uses a grease-filled access port to transport pressure measured from the outside of the PWD sub to the Pressure Module. The Pressure Module then sends the pressure data up the wire line to the interface box and computer located at the top of the hole.

The pressure data is monitored and stored by the standard RivCross software used with the Paratrack-2 system. The pressure can be viewed in real time. It is also stored for later use. The software allows easy graphical representations of pressure variations with time, an example of which is shown in Figure 3. Alarms can also be set in the software and will trigger if pressure limits are exceeded during drilling.

Because it is capable of giving a rapid indication of an increase in downhole pressure, the measurement of pressure while drilling is an effective technique to reduce the risk of bentonite (drilling mud) breakout during the drilling process. It can also help ensure that a drilled hole is kept clean and free of blockages, thus reducing operational risks.